The main focus of this installation was to reduce the amount of dredging. This mill had a very high sludge yield and had to continually dredge at a cost of close to $1 million each year. Additionally, some months the effluent BOD was getting close to their permit limits and they were worried about the additional loading from the new de-inking plant so they needed to improve the overall operations of the ASB. There was no dredging for the first three years after the installation of the baffles but they have dredged the quiescent zone once since then.

The main focus of this installation was to reduce the amount of dredging. This mill had a very high sludge yield and had to continually dredge at a cost of close to $1 million each year. Additionally, some months the effluent BOD was getting close to their permit limits and they were worried about the additional loading from the new de-inking plant so they needed to improve the overall operations of the ASB. There was no dredging for the first three years after the installation of the baffles but they have dredged the quiescent zone once since then.

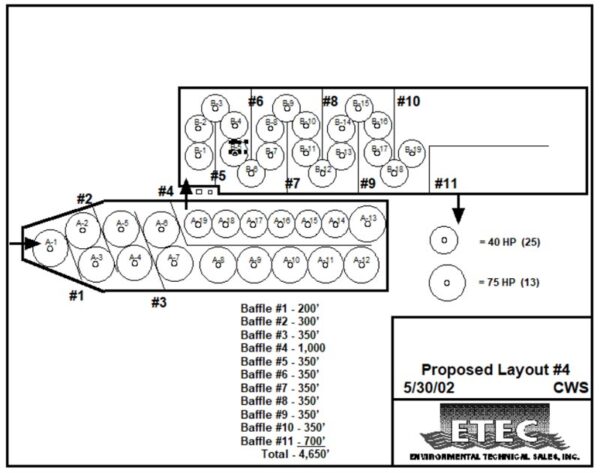

Eleven baffles totaling 4,650’ were installed in 2003 and are still in operation today.

The drawing below shows the layout and lengths of each baffle along with the placement of the aerators. The 75 HP aerators (the first 13) were spaced 150’ apart in the first two cells and the 40 HP aerators (the last 25) 100’ apart in the third cell. The baffles were designed to create 150’ channels.

The Google Earth im age shows the actual layout as it is today.

age shows the actual layout as it is today.

BOD removal rates were improved from 89.0% to 95.7%.

BOD removed/HP/day improved from 25.9 to 36.2.

Effluent BOD reduced from an average of 58.9 mg/l to 30.7 mg/l (even though they started up a new de-inking plant after the baffle installation which increased the influent BOD increased by 18.1%).

Effluent temperatures decreased from an average of 84.9 F to 80.8.

Contacts: Available on request