Industrial & Municipal Wastewater Treatment Lagoon Baffle Curtains

We engineer solutions that have helped JPS maintain 99% customer retention and satisfaction. For generations, JPS has provided Industrial Baffle Curtains and complete wastewater lagoon solutions. From plotting the exact contour of the basin of a lagoon to provide an exact fit to engineering treatment efficiencies and recommending the layout of all components to fabricate and manufacturing the baffle curtains to a precise fit – JPS pulls it all together with our turnkey installation. This is why JPS offers a full two to five-year warranty. Once installed, JPS can be called on for maintenance, review or modifications. Each JPS Baffle Curtain is custom-manufactured using a patented method that employs silicon-treated nylon stitching and are built so well, some have been in service for more than 20 years.

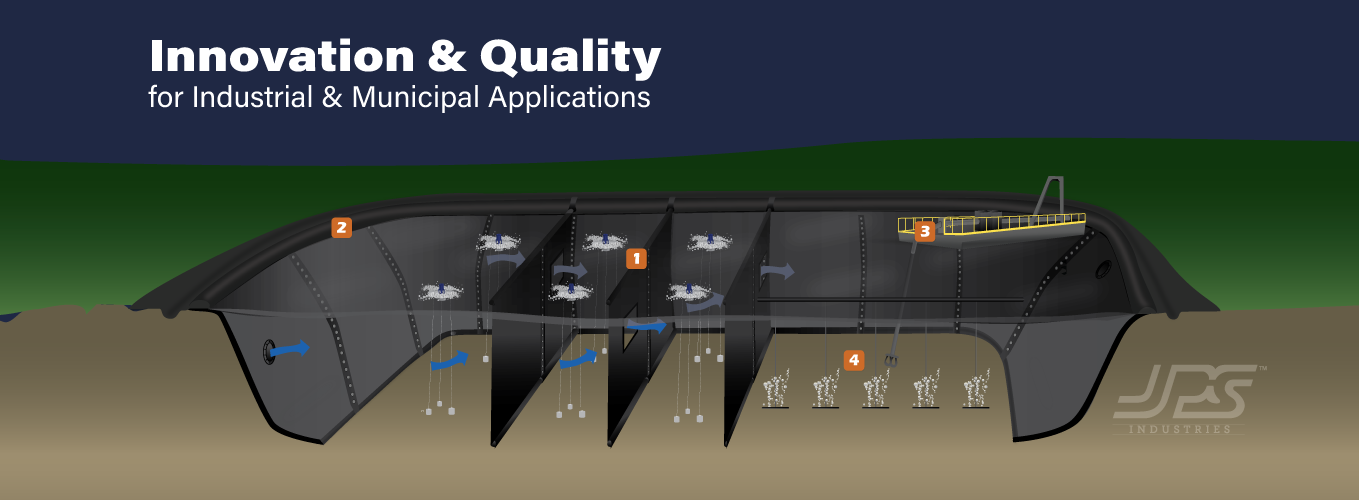

1: JPS Baffle Curtains

Our custom-built Baffles Curtains, for industrial and municipal applications, are engineered to withstand severe and extreme environments. This is due to time tested craftsmanship, construction, quality materials, and installation. We are proud to call them the best baffle curtains in the world!

2: JPS Erosion Barrier

JPS Erosion Barriers are built to protect a lagoon embankment from erosion caused by extreme elements and aeration turbulence. Paneled construction allows easy access to equipment, maintenance, and custom-fit individual panels, aid to maintain uniform rates of linear expansion.

3: Maintenance & Repair

We provide maintenance and repair of complete wastewater lagoon systems including baffle curtains, erosion barriers, surface aerators, clarifier inspection, air laterals, river outfall inspection, screen cleaning and much more and are prepared to have a dive team on site within 24 hours.

The Benefit of JPS Baffle Curtians

Engineered retention time: Given the opportunity water will take the path of least resistance, this can result in short circuiting, dead zones, sludge build up and inefficient treatment. Implementing a baffle system to engineer a specific water flow pattern can optimize treatment and retention time.

No JPS Baffle Curtians

Random Flow Pattern

Water will go directly from the inlet to outlet of a lagoon. This results in decreased retention time and reduced BOD removal. The dead zones are not treating waste and the cost to operate these aerators is lost.

JPS Baffle Curtian

Flow Pattern

The JPS Baffle Curtains pushes the wastewater into a serpentine flow pattern, forcing the water through specific columns where the aerators can maximize effectiveness, resulting in increased retention time.

About JPS Baffle Curtains

About JPS Baffle Curtains

JPS Baffles are custom built for industrial and municipal applications using the most durable materials and construction techniques available. While both applications are designed to similar specifications, JPS Industrial Baffles are engineered with reinforcing nylon straps to withstand severe and extreme environments. JPS Baffles are known for their durability due to the materials used, craftsmanship and time tested quality built into the design, construction and installation of every JPS Baffle Curtain. We are proud to call them the best baffle curtains in the world!

JPS products are engineered systems, custom-designed and precision-manufactured – specific to each application and environment. Installed in the most demanding municipal and industrial processes, many JPS Baffles and other products continue in service more than 20 years later. Industries served by JPS include: Pulp and paper, food processing, chemical manufacturing, oil storage and transport, power generation and more along with many municipal installations.

JPS has pushed the limits of many materials for decades, with one thought in mind – “How can we make a stronger baffle and make it last longer?” Today, JPS Baffles are hand constructed using the strongest nylon scrim available, with rip stops every 4th filament of the material scrim to help prevent tearing. Our anchor system is cast concrete blocks along with a minimum ballast of 5/16-inch galvanized steel chain sewn directly into a special hem in the bottom of each baffle section. Special nylon straps, which maintain a tensile strength between 12,000 lb. and 20,000 lb., are sewn into the sides, tops and bottoms of all sections. All hardware is 304 stainless steel. Definitely ready to take a beating.

All structural components of JPS Baffles are manufactured using nylon materials to maintain a uniform rate of linear expansion which helps to eliminate friction. Stress is evenly absorbed throughout the structure; a claim no other manufacturer can make. This is largely due to the construction techniques utilized when building each baffle section. For example, strength and flexibility is added to seams and hems by sewing them together using silicone-treated nylon thread and reinforcing specific areas as recommended by the hydrodynamic model. It is this careful attention to detail and uniformity that insures JPS Baffle Curtains will have minimal wear and tear and a long life in each application.

For generations JPS has provided complete wastewater treatment solutions. The process to build the ideal solution begins with a custom-fit based on field measurements of the lagoon by qualified JPS field technitians. JPS techs will recommend placement of all components in order to engineer treatment efficiencies, then fabricate and manufacture the baffle curtains to a precise fit.

Developing JPS baffles to fit each individual project requires engineering that is specific to each application. Design conciderations include seasonal or environment change, historical weather conditions and more. The custom-fit of each JPS baffle curtain is based on field measurements, of the lagoon, by qualified JPS field technicians prior to fabrication and installation.